|

Hologram Hot Stamping Solution: Hot Stamping Solution is a thermal transfer process that stamping hologram image(or without hologram) onto flat and contoured surfaces directly with permanent adhesion.

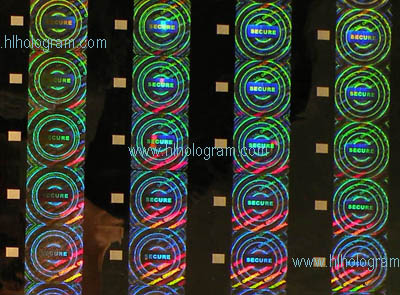

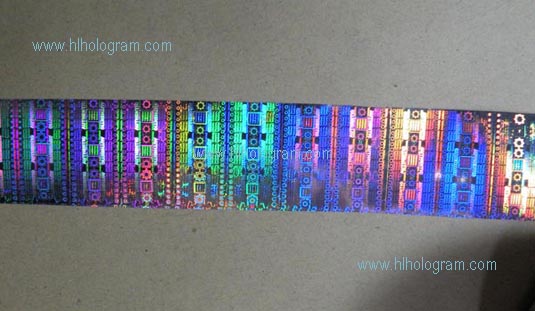

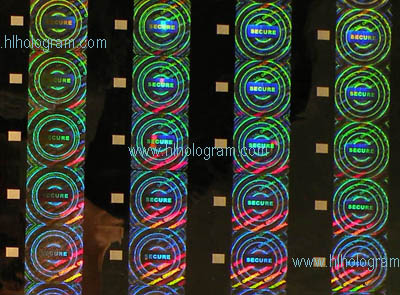

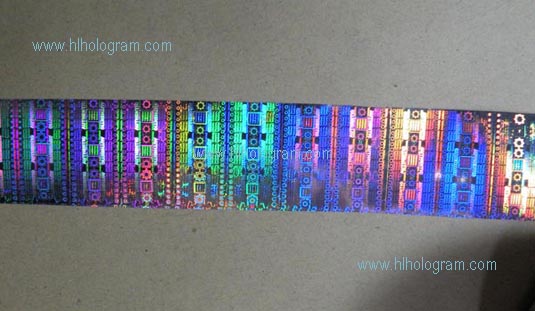

Hologram Hot Stamping Foil Brief A. General Design Hologram Hot Stamping Sample Patterns

B. Hologram Hot Stamping Foil Characteristics and Hot Stamping Temperature

C.Hologram Hot Stamping Machinery and Project & Whole Production Line Supply, Technology Transfer and Training

D. Hot Stamping Machines and Equipment & Hot Stamping Process

E. Hot Stamping Solution for Variety of Products.

Hologram

Hot Stamping Foil

, is clean and simple security and decoration solution without smearing or scratching for all kinds of smooth substrate.

Hologram Hot Stamping Foil Stamping Temperature :

There're several types of hot stamping way to transfer hologram onto substrate

A. Up-and-down and platen Stamping Presses approximately 105 Celsius

B. Cylinder Stamping Presses 130 - 150 Celsius

C. High-speed Rotary Stamping Presses 190 - 220 Celsius

Hologram hot stamping foil without register eye mark (white photo cell).

Hologram hot stamping foil without register eye mark (white photo cell).

.jpg)

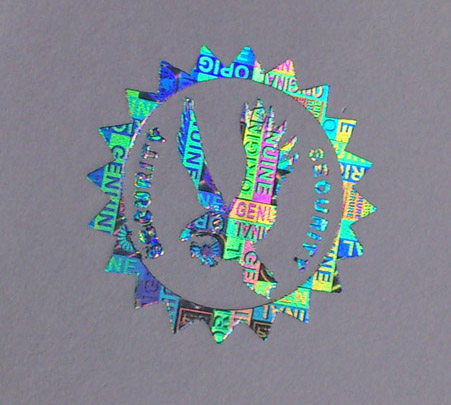

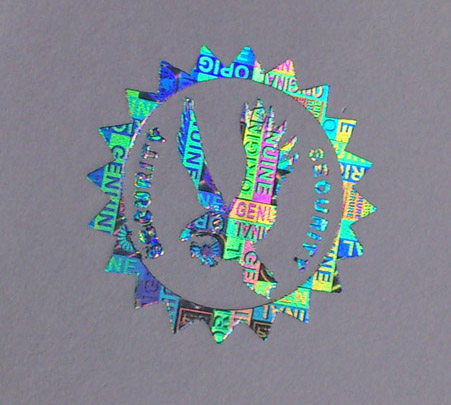

Hologram hot stamping logo made by wallpaper design holographic hot stamping foil by hot stamping.

Hologram Hot Stamping Foil Main Characteristics :

1. Small, medium and large area stamping is available

2. Good adhesive properties on Paper, PVC card, ABS , PS & PVC, Wood, Nylon, Leather, Painted Metals, Cardboard, Labels, Plastic, etc

3. Good result of over printing on Hot Stamping Image

4. It's suitable for all kind of hot stamping machines which are manually or automatically, up & down or rotary type machine

5. Hot stamping image has high shininess and gloss, without smearing or scratching

6. Hot stamping image is resistant to heat,

Hot Stamping Foil Stamping Foil Specification

Width of Foil: from 25mm to 640mm in roller

Standard Foil Size:

120meter * 64cm *12micron

280 meter * 64cm *12micron

2500 meter * 64cm *12micron

5000 meter * 64cm *12micron

Or any length according to customer's requirement

Thickness: 12 micron

Types: hot stamping to Paper, PVC card, ABS , PS & PVC, Wood, Nylon, Leather, Painted Metals, Cardboard, Labels, Plastic, etc.

Patterns: Generals or Customized Design

Colors of Foil: Silver, Golden, Red, Blue, Green or any customized color according to requirement

Any customized requirement

and specifications are available under our good service.

Hologram hot stamping foil with register eye mark (white photo cell).

How to select Hot Stamping Foil?

1. Choice of hot stamping foil

There're a variety of types of hot stamping foil , applied to different purposes, in accordance with the relevant technical guidelines to choose the right hot stamping foil . We have lots generic design hologram hot stamping foil in wallpaper design and with register mark as well. We can produce customized design hologram hot stamping foil according to customer-specific packaging stamping characteristics and requirements . After choosing the model of hot stamping foil , stamping temperature, pressure and time stamping also should be set according to actual needs.

2. Hot stamping temperature

When hot stamping temperature is too low , the gilt after stamping film has poor adhesion. When stamping temperature is too high , the hologram image will get white and gloss. So engineer can use thermometer to measure the actual temperature of the surface of hologram hot stamping foil gilt layer. Sometimes the tempreture show on hot stamping equipment has different data. We cannot only rely on the instrument display. Different hot stamping etching area in different locations sometimes produce unacceptable temperature deviations too. In addition, when the equipment in hot stamping process, the temperature is lower than the shutdown temperature . Etching temperature difference between different locations is also crucial for the quality of stamping .

3 . Hot stamping time

For some good performance stamping machines, hot stamping time (referring to time that the hot stamping mold contact the back side of hot stamping foil ) , is independent of the stamping speed independently adjustable . For the simple structure stamping machine , stamping speed up the pace would mean to shorten the inevitable imprint of time , in this case can only change the stamping speed time to get the right impression .

4, Hot stamping pressure

When hot stamping pressure is too low, the hologram transfer effect will be poor, particularly gets serious for material such as thick paper, embossed paper or leather. Similarly, The pressure between etching mold and t the substrate surface uniformity is also very important. So before hot stamping on the substrate, to adjust the position of mold and material is very important.

|

![]() English

English ![]() French

French ![]() German

German ![]() Spanish

Spanish ![]() Portuguese

Portuguese ![]() Italian

Italian ![]() Russian

Russian ![]() Romanian

Romanian ![]() Bulgarian

Bulgarian ![]() Hungarian

Hungarian ![]() Czech

Czech ![]() Danish

Danish ![]() Suomi

Suomi ![]() Turkish

Turkish![]() Swedish

Swedish![]() Norwegian

Norwegian![]() Slovenian

Slovenian ![]() Polish

Polish![]() Croatian

Croatian ![]() Slovak

Slovak ![]() Maltese

Maltese ![]() Lithuanian

Lithuanian![]() Latvian

Latvian![]() Slovak

Slovak ![]() Afrikaans

Afrikaans ![]() Arabic

Arabic ![]() Chinese(S)

Chinese(S) ![]() Chinese(T)

Chinese(T) ![]() Japanese

Japanese ![]() Korean

Korean ![]() Vietnamese

Vietnamese ![]() Thai

Thai ![]() Malay

Malay ![]() Indonesian

Indonesian

.jpg)