Customized Design Hologram Sticker

Hologram ID Overlay

Hologram Pouch

Hologram Hot Stamping

Scratch Hologram

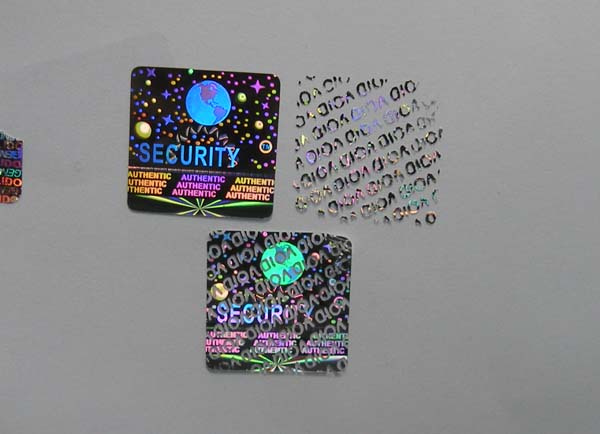

Generic Design Hologram Label

Holographic Film

Art Holography

Hologram Tape

Holographic Paper

Textile Hologram

Hologram Dome

Sequin

3D Lenticular

Aluminum Foils

Hologram Badge

Transparent Hologram

Holographic Master

Hologram Machine

Artwork Design

Big Master Selling

Hologram Technology

Contact us

About us

Why hologram

![]() English

English

![]() French

French

![]() German

German

![]() Spanish

Spanish

![]() Portuguese

Portuguese

![]() Italian

Italian

![]() Russian

Russian

![]() Romanian

Romanian

![]() Bulgarian

Bulgarian

![]() Hungarian

Hungarian

![]() Czech

Czech

![]() Danish

Danish

![]() Suomi

Suomi

![]() Turkish

Turkish

![]() Swedish

Swedish

![]() Norwegian

Norwegian

![]() Slovenian

Slovenian

![]() Polish

Polish

![]() Croatian

Croatian

![]() Slovak

Slovak

![]() Maltese

Maltese

![]() Lithuanian

Lithuanian

![]() Latvian

Latvian

![]() Slovak

Slovak

![]() Afrikaans

Afrikaans

![]() Arabic

Arabic

![]() Chinese(S)

Chinese(S)

![]() Chinese(T)

Chinese(T)

![]() Japanese

Japanese

![]() Korean

Korean

![]() Vietnamese

Vietnamese

![]() Thai

Thai

![]() Malay

Malay

![]() Indonesian

Indonesian

Thicknessness of Hologram Base Material We have different thickness of hologram sticker base material-metalized Aluminum film in thickness of 0.025mm, 0.036mm, 0.050mm. We also have different pressure sensitive material to make different hologram sticker. 25 Micron thickness is default thickness of our hologram stikcers. We have different color and pattern released material in thickness of 25micron in stock. We also can make customized thickness of hologram base film to satisfy special requirement

Hologram Ssticker Samples with Different Thickness 25 Micron 36 Micron 50 Micron 25 micrn(0.025mm) Hologram Sticker The weight of 1000 sheets hologram sticker with thickness of 0.025mm is 3.0 kilograms

Silver color hologram sticker. Silver color aluminum PET foil in 25 micron thicknes.

Silver color holographic sticker. Silver color aluminum PET foil is the material for this sticker.

Silver color holographic decal . Silver color aluminum PET foil. 25 micron thichness

Silver color security hologram sticker. VOID, tamper evident, silver color aluminum PET foil is the material for this sticker. 25 micron.

Silver color secure holographic sticker, tamper evident, special shape cutting. 25 micron thickness.

VOID pressure tamper evident pattern released holographic sticker. WARRANTY hologram. stock hologram sticker

Pressure tamper evident pattern released with word small ' VOID' hologram stickers. The sticker leaves VOID word as residues when peeled off. GENUINE Hologram, 25 micron thicknss. Stock holographic sticker

Honeycomb pressure tamper evident pattern released holographic sticker. This holographic label leaves beehive shape residue on paper after sticker peeled off. Stock holographic sticker. 30mm*10mm.

Holographic label with dual laser etched serial number 'A10012679' , This double serial number is one set numbering for security.

Holograms made by individuals are usually exposed on very high resolution photographic film coated with a silver halide emulsion. Holograms made for mass production are exposed on a glass plate pretreated with iron oxide and then coated with photoresist. The photoresist material will chemically react to the specific wavelength of light that will be used to create the hologram. Because of their availability at a relatively low cost, helium-neon lasers are most commonly used by individuals who make their own holograms. Commercial hologram manufacturers use different laser types such as ruby, helium-cadmium, or krypton-argon ion. After exposure, the film or photoresist plate is processed in chemical developers like those used in photography. Both nickel and silver are used to make the production masters that will be used to stamp multiple copies of the holograms onto polyester or polypropylene film. Aluminum is used to create the reflective coating on the back of embossed holograms.

|

|

|